Engineering Services

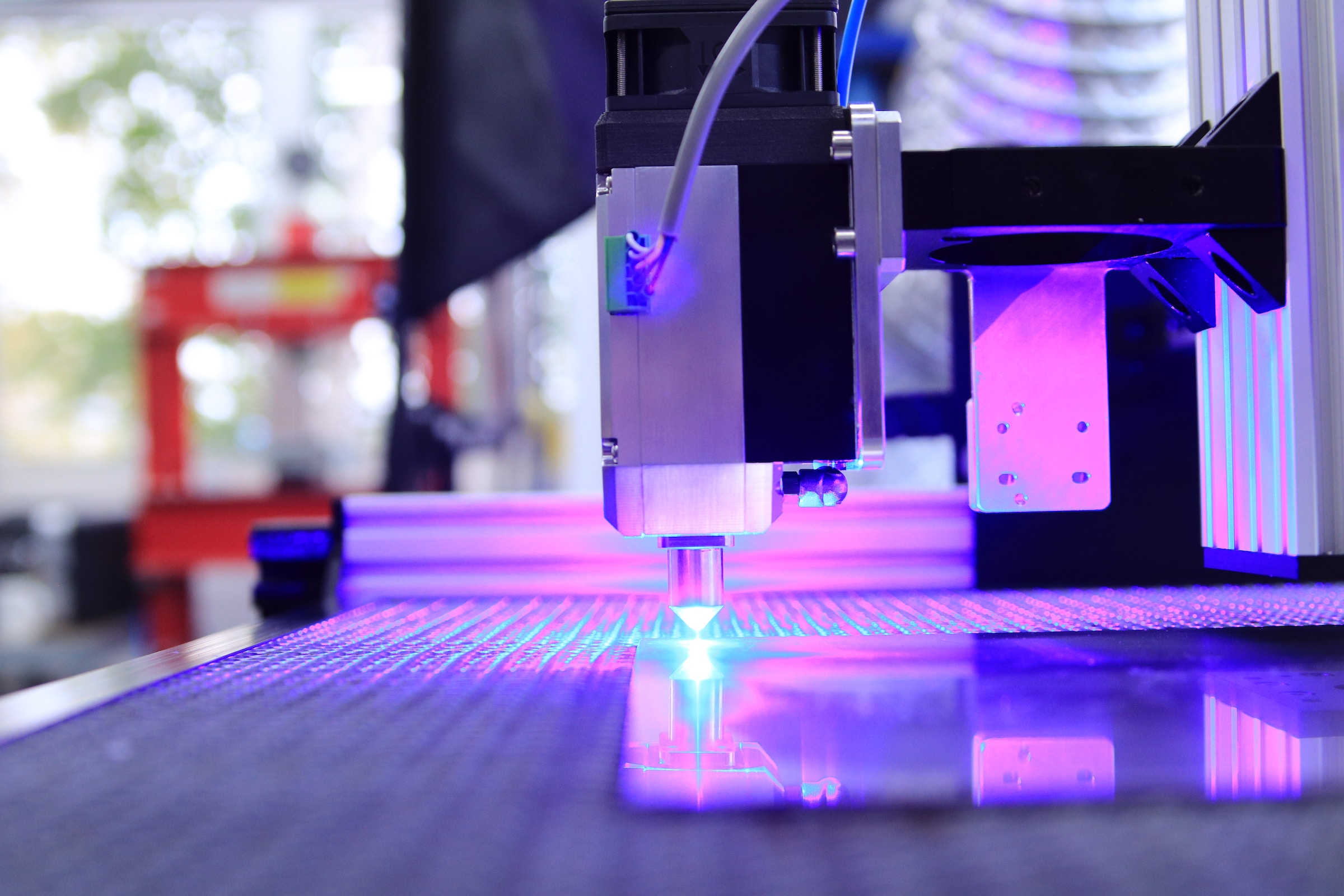

For a Precision Engineering Company incubated in Stanford University focusing on Micro-irrigation using Laser Technology

Technology transfer in Precision Engineering, leading Technical Operations, Project migration into India from overseas locations in Asia and USA for Manufacturing and Technology Development, Team development for Operations, Import substitution, Technology Development, QA, SCM/Logistics and Offshore Manufacturing, SOP development/training roll-outs, Capex Purchasing/commissioning, 3PL appointments, Vendor development, COGM/Margin improvement, Production ramp-up, Packaging development, Formulation management, Productivity improvement, Core Values development and Team motivation. Facility search & location, Negotiation of Lease agreements, Statutory compliances to Factories Act, Shop Act, Obtaining Panchayat No Objection Certificates, Pollution Control Board Clearances, VAT Registrations including Legal Metrology, Electricity Board clearances, Import-Export Certification Registration and Import clearances, Core Values development and Team motivation.

For a large Engineering Group:

Engagement with a JV Company employing over 2000 employees, provided direct management inputs that ensured appropriate relationship management with Vehicle manufacturers, distributors, coalfields / State Transport undertakings, retail chains and high volume retail outlets. Developed the market research and advertising strategy for re-launch of Engineering products to DOT 3 standard (Department of Transportation USA).

Ensured responsible above the line marketing spend, management of the advertising campaign and contact program with distributors/high volume dealers/fleet owners and leading vehicle service outfits leading to the Successful product re-launch. Improved the quality and visual appeal of packaging and on-pack printing. Successfully defended the trademark against spurious brand imitations. Ensured Marketing/logistics on an All India basis with inputs for effective control of Spare parts Warehousing, supply chain, vendor management, manufacturing plant, Pick-pack operations, packaging and inventory management.

Modernised the Warehousing system and packaging plant. Developed the Electronic forecasting and sales planning system for individual SKU’s. Resulted in revenue and growth targets being exceeded despite widespread industrial recession. Developed the Institutional markets in the Coalfields and State Transport undertakings. Inputs provided to Organise the Distributors conference at Hong Kong. Involved in implementation and award of the ISO 9002 standard.

For a leading manufacturer of Power Transformers and On-load Tap Changing Gears:

Provided inputs for product marketing Support to the Power Transformers and OLTCG Tapchangers divisions. Inputs on Tender Document Preparation and Production/Design Liaison. Exhibitions and technical literature development.